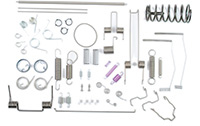

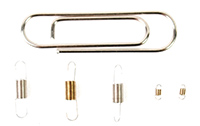

Seihatsu can tool and temper the spring which dire meter is φ0.1~φ8.0. The sizes and shapes of springs are many. The cutting-edge wire forming machines enable us to manufacture highly precise and highly durable springs. Additionally, Seihatsu is good at bending and spiral forming. These products are used for critical safety parts of automotive and developing fluid transportation device of multi-function printers.

The latest servo press machines such as 250t (W) enables us to stamp and temper plate spring that thickness is 0.1~2.6. Also, precision stamping parts that thickness is 0.03~2.0 are manufactured. Although thin spring material is more difficult than normal materials due to spring back and the change of shape by tempering, we have enough know-how about various materials and shapes.

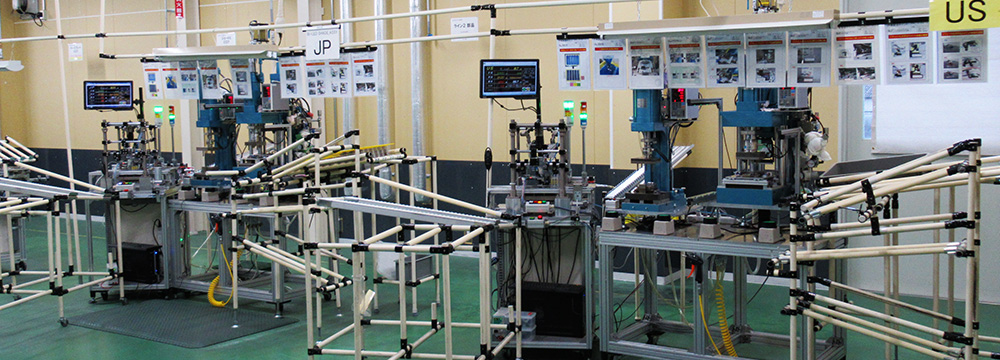

Commencing with the critical safety parts, Seihatsu is manufacturing a lot of different assembly parts. By self-manufacturing stamping parts and spring, it is possible to implement streamlined production and it enables us to effectively manufacture ASSY parts. Also, jigs and inspection machines are designed and made in house.

The mold and die・Jig・Inspection machines can be designed and made in house. It enables us to deal with sudden design change without delay. Also, we are good at presenting ideas of VA・VE・Suggestions for improvement.

Austempering furnace, Non-oxidization Furnace, Laser welding machine, Spot projection welding machine, Multi-Forming Machine, Degreasing machine are equipped and actively implement new machines and learn new technology.